Heavy Duty Clinched Selvage BeltingHeavy duty clinched selvage belts feature a better wearing edge surface for misaligned conveyor systems.

Clinched Selvage Belt Specification

HEAVY DUTY BELT DIMENSIONS: (1) Maximum working tension per foot of belt width given for drum driven applications only. Materials Available

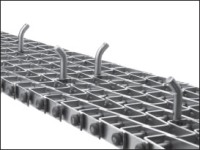

Features

Sprockets

Special Belting

|

||||||||||||||||||||||||||||||||

| Home | Products | Products | Technical Information | Applications | Glossary | Frequently Asked Questions | Contact |