Key-Turn radius belting has all the characteristics of straight-line flat wire belts, with the additional capability of making right or left turns of up to 180 degrees (360 degrees for spiral systems).

T1 - 1" x 1" Mesh, Welded Selvage

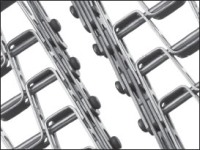

Shown with 0.062" and 0.090" thick double reinforcing links |

T2 - ½" x 1" Mesh, Welded Selvage |

Key-Turn Specifications

| |

Width |

Approx. Wgt. |

| Design |

Mesh |

Min |

Max |

(Lbs./Sq. Ft.) |

| T1 |

1" x 1" |

7" |

48" |

3.1 |

| T2 |

½" x 1" |

7" |

48" |

3.4 |

KEY-TURN BELT DIMENSIONS:

• Flat strip = 1/2" wide x .062" thick, round edge • Connector rod = 6 gauge (.192" diameter), high tensile strength

Materials Available

- Galvanized steel

- C1050 high carbon steel

- T-304 stainless steel

- T-316 stainless steel

- T-201 stainless steel

|

EDGE REINFORCEMENT

- Reinforcing links strengthen outside edges.

- Available in 0.062" or 0.090" thick T-304 stainless steel material.

- One or two links may be placed on either edge.

- Reinforcing links on both edges enable belt to be flipped for longer life.

|

Features

- Turning ability enables belt to avoid obstacles, operate in limited space, and eliminate troublesome transfers.

- Elongated slots allow pickets to nest, giving the belt the ability to turn and also providing for easy and

thorough cleaning.

- Stainless steel Key-Turn belts are USDA approved for use in federally inspected meat and poultry plants.

- H series sprockets for heavy duty belts are suitable for Key-Turn belts.

Turning Radius

- Minimum belt turning radius is equal to 2.2 times the belt width, measured on the inside radius of the belt.

- No maximum turning radius.

- For tighter turns, two or more narrow width belts divided by a rail may be used.

- Conveyor should be designed to include a straight run 3 times the belt's width before engaging sprockets

after a turn.

- Consult Keystone Manufacturing before using the belt in a non-powered turn situation, as this set-up

can cause excessive strain.

- Maximum allowable drive tension is 300 pounds.

- For belt speeds above 15 feet/minute, maximum drive tension is reduced to 200 pounds.

- Both load and return side belt supports should be either rollers or UHMW polyethylene to reduce friction

to a minimum.