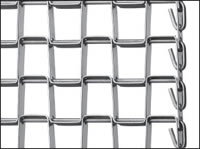

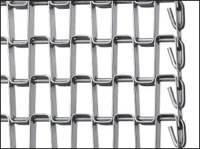

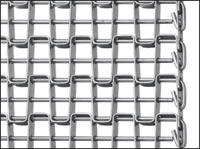

Standard duty clinched selvage flat wire belts are suitable for most general conveying applications.

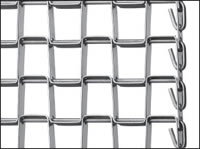

S1 - 1" x 1" Mesh, Clinched Selvage |

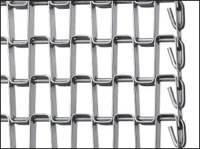

S3 - ½" x 1" Mesh, Clinched Selvage |

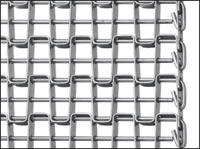

S7 - ½" x 1" Mesh, Clinched Selvage |

CLINCHED SELVAGE BELT SPECIFICATIONS

| |

Width |

Max. Tension |

Approx. Wgt. |

| Design |

Mesh |

Min |

Max |

(Lbs./Ft. of width)1 |

(Lbs./Sq. Ft.) |

| S1 |

1" x 1" |

4.5" |

240" |

480 |

1.85 |

| S3 |

½" x 1" |

4.125" |

240" |

660 |

2.20 |

| S7 |

½" x 1 Modified |

4.125" |

240" |

660 |

2.50 |

| S8 |

¾" x 1" |

4.5" |

240" |

550 |

2.00 |

STANDARD DUTY BELT DIMENSIONS:

• Flat strip = 3/8" wide x .046" thick, round edge • Connector rod = 11 gauge (.120" diameter)

• 12 gauge (.105" diameter) rods are available for S1, S3 and S7 designations.

• S8 belting is stocked in 20" and 30" widths, galvanized only. Other widths and materials available by special order.

(1) Maximum working tension per foot of belt width given for drum driven applications only.

Materials Available

- Low carbon galvanized steel

- C1050 high carbon steel

- T-304 stainless steel

- T-316 stainless steel

Features

- Mesh available in four (4) different sizes.

- Widths available ranging from 4.125" to 240".

- Strong edge that reduces chances of snagging or catching on conveyor protrusions.

- Better edge wear on misaligned conveyor systems.

- Mechanically prevents belt from narrowing under heavy loads.

Sprockets

- May only be placed in the outside drive openings for the 1" x 1" mesh. There is not enough clearance in the

outside openings of a ½" x 1" mesh to be able to position a sprocket in those spaces.